Cold Air Intake (CAI) Heat Protection Shields are crucial for high-performance vehicles, acting as insulation barriers that prevent hot exhaust gases from heating incoming cold air. Made of advanced materials like fiberglass or carbon fiber, these shields maintain cool and dense intake air, optimizing combustion and boosting horsepower and torque. By deflecting engine heat and trapping cold air, thermal barrier technology ensures optimal performance, component longevity, and prevents overheating, even in extreme conditions. Beyond automotive use, these barriers offer versatility in construction, aerospace, and manufacturing, providing cost savings, improved comfort, enhanced performance, and prolonged equipment lifespan.

Thermal barrier technology is a game-changer, offering innovative solutions for managing extreme temperatures. This article explores an advanced application: cold air intake heat protection shields. We’ll unravel how this technology safeguards vital components, enhancing performance and efficiency. From automotive engines to industrial processes, thermal barriers provide a protective cold air intake heat protection shield, enabling optimal function in challenging environments. Get ready to discover the science behind this revolutionizing concept.

- Understanding Cold Air Intake Heat Protection Shields

- How Thermal Barrier Technology Works

- Applications and Benefits of Thermal Barriers in Automotive and Beyond

Understanding Cold Air Intake Heat Protection Shields

Cold Air Intake Heat Protection Shields play a crucial role in maintaining optimal engine performance and efficiency, particularly in high-performance vehicles or those operating in extreme environmental conditions. These shields act as insulation barriers, preventing hot exhaust gases from heating up the cold air entering the engine. By keeping the intake air cool and dense, it enhances the combustion process, resulting in increased horsepower and torque.

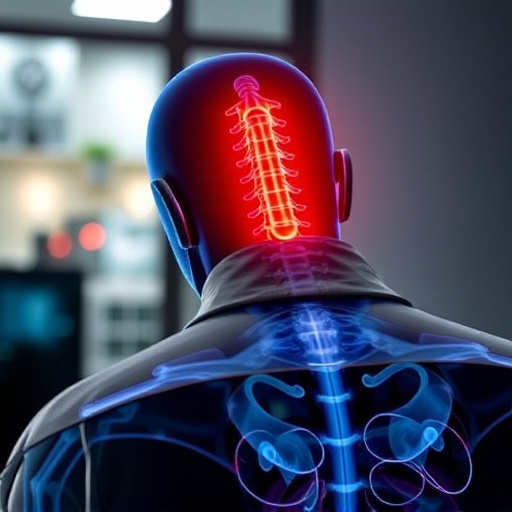

This technology is designed to navigate the delicate balance between allowing ambient air to enter the engine for efficient burning and shielding the sensitive components from excessive heat. The shields are strategically placed around the cold air intake (CAI) system, often made from advanced materials like fiber glass or carbon fiber, which offer excellent thermal resistance and flexibility. This ensures that even under extreme temperatures, the shield maintains its integrity, providing a consistent supply of cool air to the engine.

How Thermal Barrier Technology Works

Thermal barrier technology is a game-changer when it comes to protecting vehicles from excessive engine heat, particularly in high-performance cars and motorsports. This advanced system operates by creating a physical and thermal barrier between the internal combustion engine and the surrounding environment. By utilizing specialized materials that reflect and insulate heat, it effectively traps cold air intake while deflecting the engine’s radiant heat.

Imagine a protective shield that keeps the engine cool during intense driving conditions. This technology works similarly, ensuring optimal performance and longevity of the engine components by maintaining lower operating temperatures. The barrier prevents heat from reaching sensitive parts, reducing the risk of overheating and associated damage, especially in extreme weather or demanding driving scenarios.

Applications and Benefits of Thermal Barriers in Automotive and Beyond

Thermal barriers, a revolutionary technology in the automotive industry, offer more than just temperature control; they are versatile solutions with wide-ranging applications. One prominent use is in cold air intake systems, where heat protection shields ensure that incoming air remains cool and dense, enhancing engine performance. This is particularly beneficial for high-performance vehicles, improving fuel efficiency and overall driving experience.

Beyond automotive, thermal barriers find utility in various sectors. In construction, they act as insulation, maintaining comfortable interior temperatures while reducing energy costs. Aerospace applications leverage their heat-resistant properties to protect sensitive equipment from extreme temperatures encountered during flight. Moreover, in manufacturing, these barriers safeguard machinery from thermal stress, prolonging equipment lifespan and minimizing downtime due to overheating.

Thermal barrier technology, as demonstrated by cold air intake heat protection shields, offers a multifaceted solution for managing extreme temperatures across various industries. From automotive engineering to advanced manufacturing, its applications are vast and beneficial. By efficiently insulating hot components and directing airflow, thermal barriers enhance performance, reduce energy loss, and contribute to the development of more sustainable and efficient systems. As research progresses, we can expect even more innovative uses of this technology, further shaping the future of many sectors.